A novel approach to the generation of pulses with durations of only a few picoseconds is based on Raman shifting a light frequency to the Stokes range with simultaneous compression of 1 to 2 ns, 1064 nm pulses, and then following the anti-Stokes frequency shift back to the fundamental wavelength.1 This technique enables compact and relatively inexpensive laser sources. In particular, these lasers offer highly efficient generation of 3 to 5 ps ultraviolet (UV) pulses at 355, 266, or 213 nm with output average powers up to 1 W and a system cost of less than $100,000.

Micromachining metals

Micromachining is one of the most important applications for picosecond UV lasers. Due to their short wavelength and high peak power these lasers can provide minimum-diameter holes as well as minimum slit widths in metals, ceramics, and in sheets of other materials up to a few hundred microns thick. The quality of these cuts is practically the same as can be obtained with femtosecond lasers. Cuts made, for example, with 266 or 213 nm pulses don’t have heat-affected zones (HAZ) and the irregularities of the holes are typically less than 1 µm. The typical rate of UV microdrilling is 0.4 µm for a laser fluence of about 20 J/cm2. Therefore, to make a hole through 1 mm stainless steel, a picosecond UV laser has to deliver an accumulated fluence of about 50 kJ/cm2, which corresponds to an energy burst of 400 J per hole with a diameter of 1 mm. This result does not depend significantly on the pulse repetition rate of the burst, at least up to 105 to 106 Hz, so the “fastest” hole through a 1-mm-thick metal sheet can be made within a few milliseconds. For nanosecond pulses the laser fluence required for the same result is much higher and the total energy needed to make a similar hole is also significantly higher.

[Native Advertisement]

Micromachining plastics

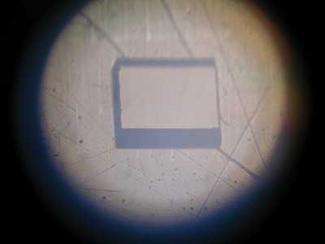

Ultraviolet picosecond lasers occupy a niche in machining and scribing of dielectrics, plastics, and resins. The display market is currently trending toward smaller displays so the quality of a cut without collateral damage and residual carbon appearance becomes that much more important. These rapidly growing markets, including LCD (liquid-crystal display) trimming, touch-screen fabrication, transparent indium tin oxide processing, and marking of plastics and other technologies require lasers for drilling holes, cutting out cavities, and making pits and ditches accompanying extraction of material to a depth of 10 to 20 µm. The primary mechanism of UV light absorption in these materials appears to be two-photon absorption with resulting photodestruction within a layer thinner than 1 µm. Short pulse width and fast plume removal avoid heat accumulation in the deeper layers. Therefore, subsequent laser pulses continue similar photodestruction while keeping residual matter relatively cold (see Fig. 1).

FIGURE 1. A rectangular 1 × 1 mm2 hole cut in 400 µm plastic sheet (nylon) by 266 nm, 4 ps pulses exhibits no obvious traces of residual carbon that typically develops as black areas covering the cut. Note that adding 1064 nm picosecond pulses causes carbon to appear and the quality of the cut deteriorates. Such peculiarities arise from the undesirable heating of the plastic by the 1064 nm pulses.

Processing of plastic and resin can also have implications for future photolithography technology. The ability to gradually remove thin submicron layers via two-photon absorption of single-picosecond pulses with fast plume evaporation without residual heat transfer to a substrate requires less laser fluence than that needed for multinanosecond UV lithography. Low collateral heating and dry sublimation together with reduced requirements to acceptable wavelengths make it possible to apply UV picosecond lasers for precise ablation technology with lower processing cost.

In some cases, there is a need to cut metal, ceramic, plastic, resin, or glass with a sheet thickness of 1 mm or more. The beam diameter then must be wide enough to provide a diffraction Rayleigh length longer than the material sheet thickness. So, for instance, to drill a 1 mm sheet with a 355 nm beam the laser-beam diameter must be at least 20 µm. For a fluence of 20 J/cm2 the corresponding laser pulse energy must be more than about 70 µJ. Hence, pulses with energy less than 100 µJ are unsuited for drilling through 1-mm-thick metal or other dense materials.

Surface structuring

Internal processing of glass and other dielectrics includes a change of refractive index, local melting, and so forth. This is important for 3-D binary-data storage, or direct writing of gratings in optical waveguides. Internal modification of glass can be achieved via two-photon absorption and avalanche ionization using picosecond UV pulses.2 In particular, 213 nm picosecond pulses in low-germanium-content and boron/germanium-codoped optical fibers at a total fluence about 4 kJ/cm2 achieves a refractive index change of about 10–3.3, 4 This capability could be important for writing fiber gratings for wavelength-division multiplexing.

Silicon-wafer processing is a good example of surface structuring. The silicon (Si) wafer, when irradiated by UV picosecond pulses, changes surface morphology and, depending on processing conditions, acquires microcolumn structures.4 This is particularly interesting for fabrication of solid-state consumable Si matrices that can replace the inconvenient liquid matrices currently used in mass spectrometry. Such replacement allows users to identify the results of mass-spectra measurements more easily because of lack of complex matrix fragments overshadowing the analyte identification.

Spectroscopy and confocal microscopy

These applications are intended to help build images and “chemical” maps of molecular distribution in human tissue and cells. They are also important for modern pharmacology (see Fig. 2).

FIGURE 2. An experimental setup provides fluorescence-spectrum measurement combined with a spatial filter for confocal microscopy selectivity.

In the case of two-photon absorption, the energy absorbed by tissue can be estimated by:

where E is the laser fluence limited by the damage fluence Ed, A is the illuminated area, α is the coefficient of two-photon absorption depending on the laser-beam intensity I and wavelength λ. It is obvious that the fluorescence energy, proportional to:

where E is the laser fluence limited by the damage fluence Ed, A is the illuminated area, α is the coefficient of two-photon absorption depending on the laser-beam intensity I and wavelength λ. It is obvious that the fluorescence energy, proportional to:

will increase if the laser pulse peak power P = IA is higher. Thus, the shorter the laser pulse at the optimal wavelength, the more fluorescence emission can be achieved (via photons revealing information about molecules that are hidden by other molecules not exhibiting high-efficiency two-photon absorption). This is very important for studying human tissues and for forensic investigations.

Ranging and sensing

Picosecond pulses can be applied for ranging and coordinate designation up to tens of miles depending on pulse energy. Depending also on receiver sensitivity few-milliJoule pulses may provide a relatively strong return from diffuse targets located at distances of up to a few miles.

Many applications are particularly suited to using eye-safe picosecond lasers. Such lasers can be applied for urban profiling, vehicle collision avoidance, security-zone monitoring, and high-precision positioning systems (both global and local).

Picosecond pulses are also suitable for analytical sensing in the newest generation of lidars. In particular, coherent anti-Stokes Raman scattering (CARS) can select low concentration admixtures (NO, O3, SO2, for example) in air and the efficiency of that process becomes higher if the widths of pumping and probe pulses are shorter than the phonon lifetime associated with molecular collisions in air (about 150 ps). By varying the time delay of the probe pulse the magnitude of parasitic nonresonance signal can be decreased by more than three orders of magnitude.5 Moreover, self-focusing of picosecond pulses in air can augment the CARS wave interaction, which allows taking low concentration measurements at long distances.

Laser-induced dissociation and ionization

Today the most developed analytical technique associated with short-pulse laser ablation is elemental analysis of atoms and ions excited in the processes of laser-induced breakdown spectroscopy and/or atoms and ions transportation after ablation via inductively coupled plasma to another measuring device, such as a mass spectrometer. However, a new approach to analysis of organic molecules with the help of picosecond and subpicosecond pulses is on its way.

The two (or more) photon dissociation and ionization of compounds and labile molecules in the field of few-picosecond or shorter UV-laser pulses can provide selection of the molecules of interest because of their varying degrees of fragmentation. The short interaction time allows completion of the dissociation or ionization before the intermediate levels can be significantly depleted by intermolecular relaxation processes. This process results in mass spectra suitable for identification of compounds and samples.6

The combination of a very simple and inexpensive stretching and compression technique with nonlinear phase conjugation allowed us to develop a new family of powerful UV lasers with pulse energies of about a hundred millijoules and pulsewidths of a few picoseconds. This is a new encouraging tool for approaches requiring high-energy picosecond pulses, in particular for EUV generation and for development of lidar exploiting nonlinear beam-propagation features.

REFERENCES

1. K. Latone, G. Pasmanik, A. Spiro, 18th Annual Solid State and Diode Laser Tech. Rev. (SSDLTR 2005). Technical Digest, ALT-3 (2005).

2. I. Miyamoto, A. Horn, J.Gottmann, J. Laser Micro/Nanoengineering 2(1) 7 (March 2007).

3. S.Pissadakis, M.Konstantaki, Materials Processing Express 13, 2605 (2005).

4. B.N. Walker, G. Pasmanik, A.Vertes, American Physical Society Ann. Meeting, Abstract C1.00167, New Orleans, LA (March 10, 2008).

5. C.Weickhard and K. Tonnies, Rapid Communication in Mass Spectrometry 16, 442 (2002).

6. S.Roy, T.R.Meyer, and J.R. Gord, Applied Phys. Lett. 87, 264103 (2005).